.jpg)

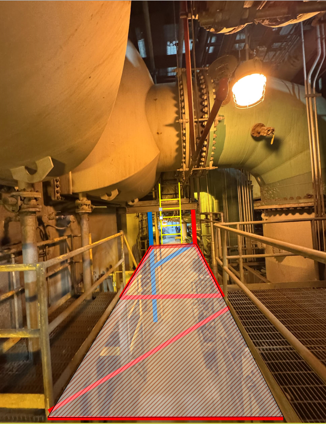

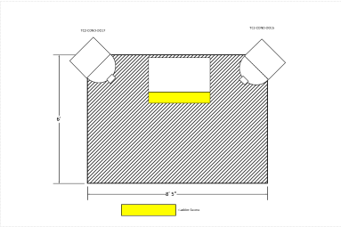

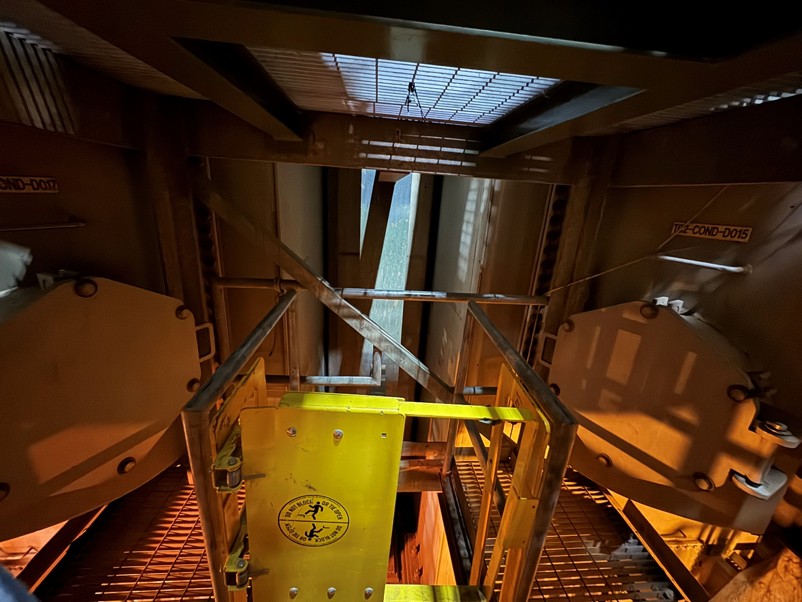

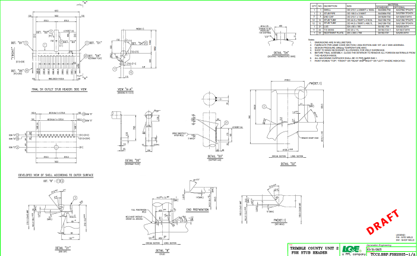

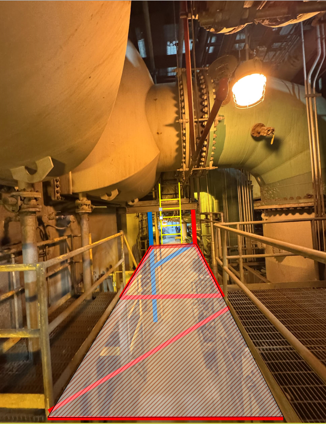

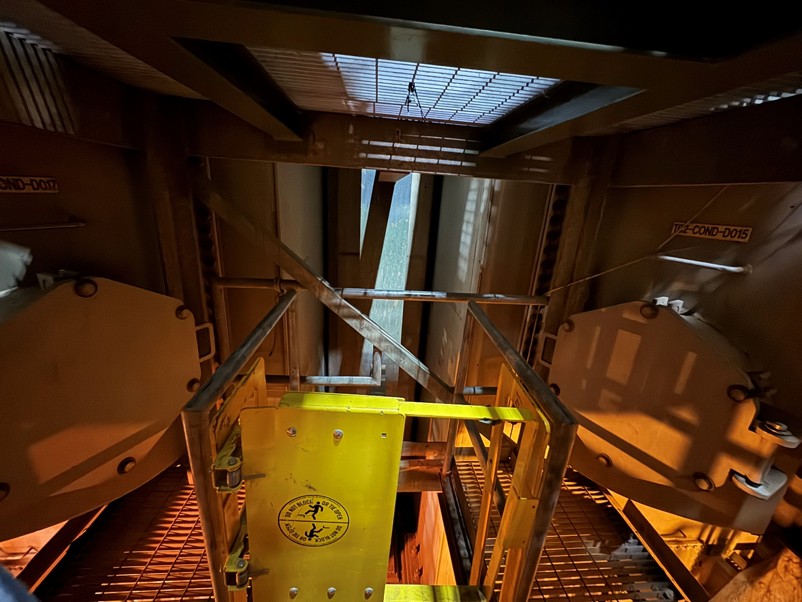

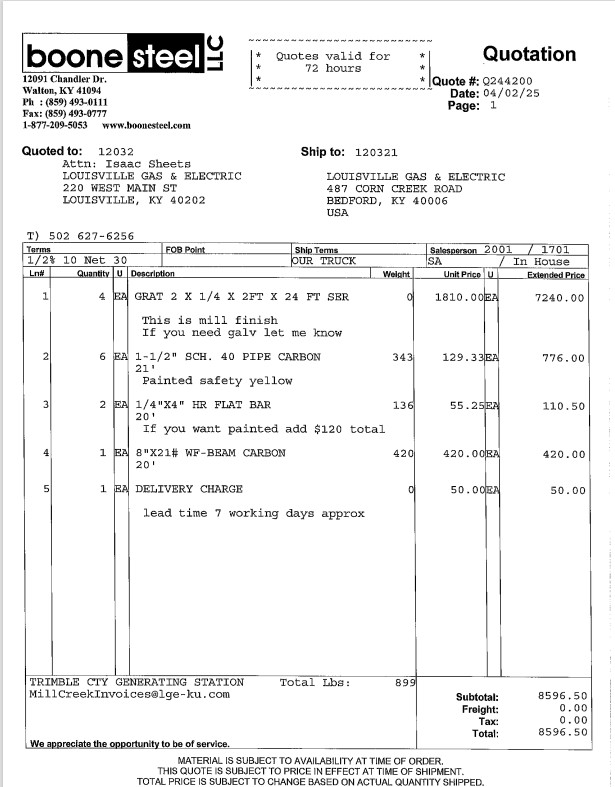

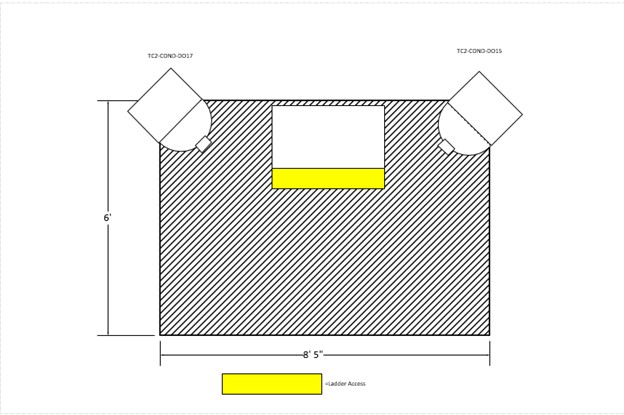

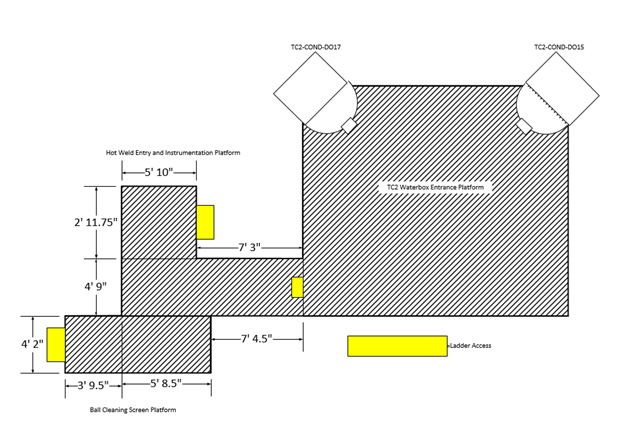

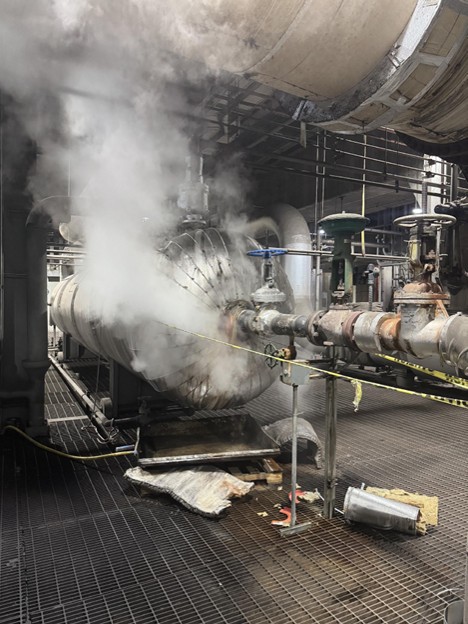

This was my own personal project that I worked on. A safety issue was shown with an entrance to one of the coal units. The unit's enterance was to dangerous to pull people out of and I was tasked with redesigning it so it would be safer. I had to create a design, get it approved by engineering, then have it approved by mechanical maintenance, operations, and then pitch my design and budget to management in order to have it fully approved. There were several iterations to my design and each one forced me to do more walkdowns and redesign everything. The picture on the top left is the final design, the picture on the bottom left is the enterance and it's issue, the picture on the to right is the design in visual before my design, and the picture on the bottom right is after my design. The picture below is the order to Boone Steel, however the photo got corrupted when I transfered it over last May and I didn't realize until I put this website together and by then it was to late. An issue I had was that my designs kept getting in the way of mechanical maintenance and operations, meaning that if my design were to be created they wouldn't be able to do their jobs as the structure would get in the way. Eventually I was able to come up with the previously shown design and it worked. I then had to send in an order to Boone Steel in order to get all of the material to build it. Learning how to communicate with another company was pretty interesting but I was able to work it out. The one thing I learned is that it takes time to get materials, and it's expensive. The total cost of all of this was around 25k, which for me was absolutely insane. A very important thing I learned was that no design is ever finalized until it's actually created. I always had to go in and make small edits or change something here or there. I learned a ton from this project as well and I am extremely grateful LGE gave me this opportunity.

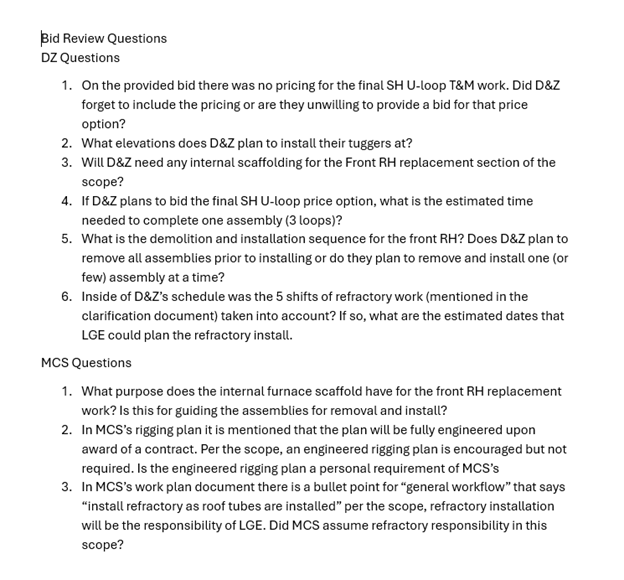

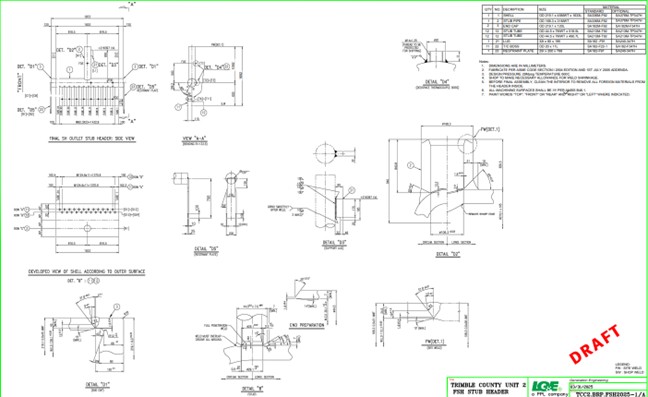

In addition to handling my own project I also assisted with my mentor's projects. He was replacing a waterwall, which is the side of a boiler that contains tubing needed to turn water into steam, and was fixing a reheat. Obviously I couldn't help design the project as it was already in progress but I could learn a ton from it. I was able to learn the commercial side of his projects. I was able to join in on lots of bid meeting where I learned how the project was presented, what types of questions were asked, and how the bid meeting was supposed to go. I also learned how to create clarifying questions. These are questions that are asked and we cannot answer them immediately. I also learned how bidding works, and how as engineerings we make decisions that affect peoples lives, buisnesses, safety, and so much more. I also learned about the art of bribing and how companies will sometimes bribe the engineer with gifts, money, etc so he or she will choose their bid. I learned that engineering ethics plays a huge role in how we handle ourselves and the decisions we make. I also learned about planning. At LGE there are a lot of projects that all happen at the same time, and our mechanical maintenece team, and our Instrument and Electrical team, had a lot of projects they had to work on. We had lots of meetings with other engineers about how to schedule each project so that all the work can be done. In addition sometimes multiple projects are happening in the same place, and we had to make sure that the workers were able to complete their tasks in a safe environment and not get injured from some other project. In addition communication with management was imperative and something we did regularly. In projects like these it's exteremely important to keep them in the loop and also format the emails properly. LGE taught me how to properly format an email and the correct language to use as well.

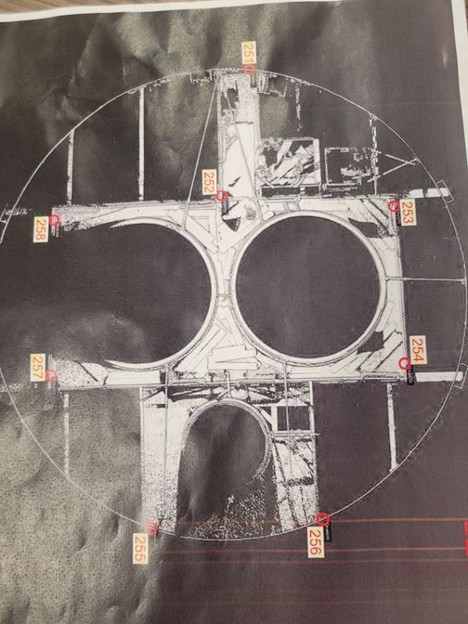

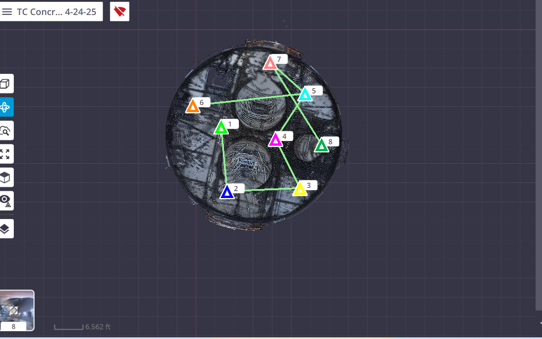

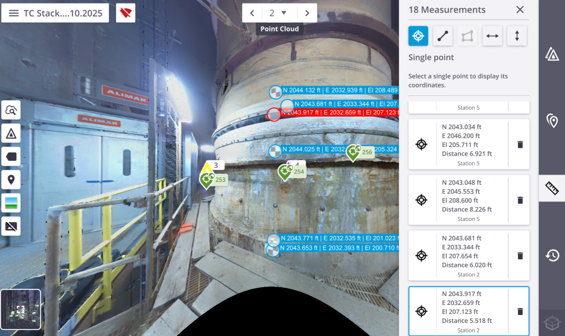

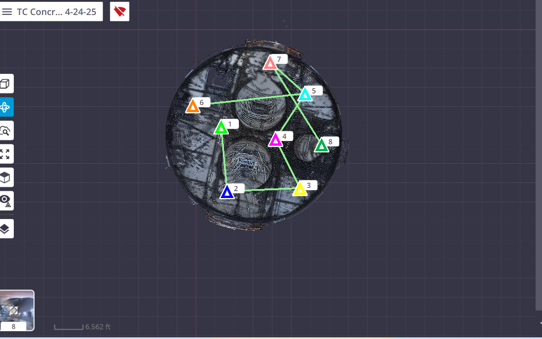

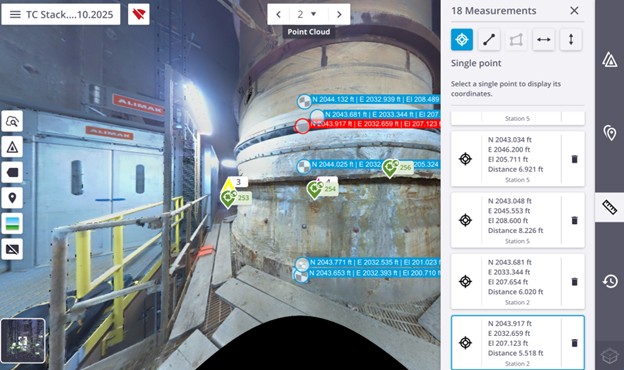

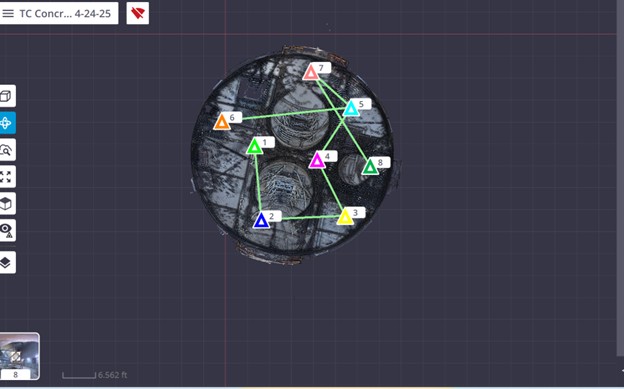

I also assisted in other projects. One of those projects was a Stack Project. That was the name of the project. The stack is the place that the flue gas goes to be pumped into the air after it has been cleansed of polutants, see the photo right under this. The stack was being monitored to see if the expansion joints had moved, and if so how much had they moved. We used a scanner, that we were told was called The Scanner, to use LIDAR and take imagery of the stack. The images you see around this text are examples of that photography. We would take it to different levels and take in depth scans to gain accurate measurements. In addition we could combine different scans, which is the top right photo, and create 3d imagery of the floor. This helped us gain accurate measurements to a higher quality. In addition we would also take manual measurements of the expansion joint. Using tape measurers, electric measurers, etc. I assisted in collecting these measurements, taking scans, and combining scans together. We all had to work as a team in order to collect accurate data, and it taught me a lot about safety, as we were extremely high up, and how to work effectively on a team.